Custom Alloy 455® Stainless Steel Technical Data, Precision Alloy Services

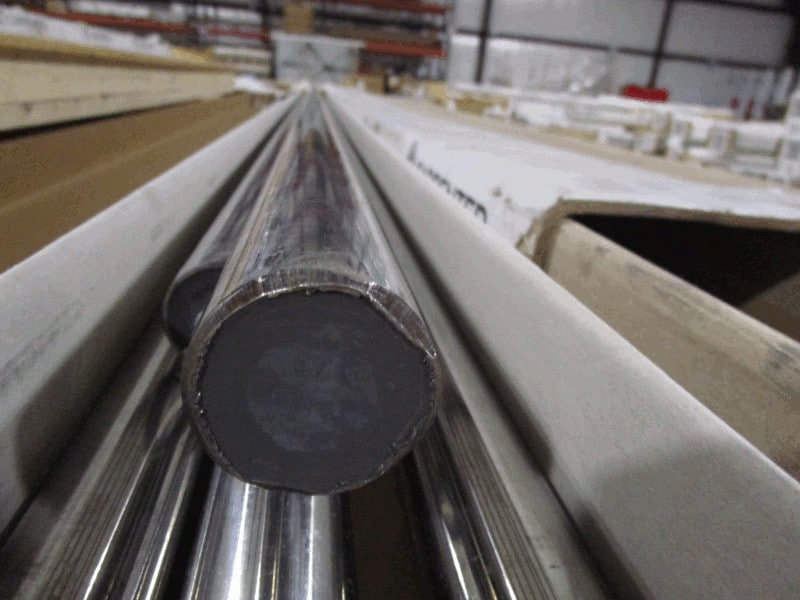

If you’re searching for the perfect combination of strength and corrosion resistance in an alloy, then look no further than Custom Alloy 455® Stainless Steel from Precision Alloy Services. Its unique durability makes it popular with manufacturers who need to provide a high-performance product to their customers. For example, this alloy is used in aerospace applications and oil field equipment where reliability and long-lasting performance are key. In this blog post, we will explore its properties as well as how precision alloy services can help make sure that your requirements for quality and consistency are met every time. So let’s get started!

Overview of Custom Alloy 455® Stainless Steel Technical Data and Precise Alloy Services

Custom Alloy 455® Stainless Steel is a high-strength alloy that is used in a variety of industries that require superior performance, such as aerospace, medical, and oil and gas. This unique alloy is sought after for its excellent corrosion resistance, good strength, and high ductility. At Precise Alloy Services, we offer a comprehensive range of Custom Alloy 455® Stainless Steel products and services, providing customers with the precise components that they require. With extensive technical data available, we ensure that each product is made to the exact specifications to meet the individual needs of our customers. Our team of experts has the know-how and experience to deliver outstanding results, providing solutions that are tailored to each customer’s unique requirements.

Understanding the Benefits of Custom Alloy 455® Stainless Steel

When it comes to choosing the right material for various applications, Custom Alloy 455® Stainless Steel is a popular option to consider. This type of steel offers several benefits, such as excellent corrosion resistance, high strength, and good ductility. These characteristics make it an ideal choice for use in the medical, aerospace, and automotive industries. Plus, with its high level of hardness and durability, Custom Alloy 455® Stainless Steel is well-suited for applications where wear and tear is a concern. So, whether you are designing a component for a life-saving medical device or looking for a sturdy material to use in a high-stress application, Custom Alloy 455® Stainless Steel is definitely worth considering.

Factors Affecting the Performance of Custom Alloy 455® Stainless Steel

Custom Alloy 455® Stainless Steel is a type of stainless steel that has gained popularity in the manufacturing industry due to its strength and corrosion resistance. However, like any other material, the performance of Custom Alloy 455® Stainless Steel can be affected by various factors. One of the main factors is the conditions in which it is used. For instance, exposure to high temperatures can lead to a reduction in its strength, while exposure to chlorine or other chemicals can cause corrosion. The mechanical properties of the material can also be affected by the processing technique used during manufacturing. It’s therefore essential for manufacturers to understand these factors to optimize the performance of Custom Alloy 455® Stainless Steel in their specific applications.

How to Choose the Best Custom Alloy 455® Stainless Steel for Your Project

Custom Alloy 455® Stainless Steel is a top choice for various projects that require high strength, corrosion resistance, and durability. However, selecting the best grade for your specific project can be quite challenging. The key is to understand the characteristics of each type of Custom Alloy 455® Stainless Steel and how they can meet the demands of your project. Factors such as the project’s environment, expected stress level, and required machining ability all play a crucial role in determining the best fit. Consulting with a trusted supplier or expert in the field can also help you make the most informed decision. Choosing the right Custom Alloy 455® Stainless Steel may seem overwhelming, but with careful research and consideration, you can ensure your project’s success.

Applications that Require Precision Alloy Services

In this day and age, precision is key when it comes to technology and engineering projects. That’s where precision alloy services come in – by providing specific alloys tailor-made for certain applications, companies can be assured of a higher level of accuracy and efficiency. From medical devices like pacemakers to aerospace components, these specialized alloys are vital in ensuring optimal performance and reliability. Just imagine the consequences if something as critical as a life-saving medical device or a component of a rocket was produced with subpar materials that weren’t up to the task. By utilizing precision alloy services, companies can rest easy knowing that they’re using the best possible materials for their specific needs.

Tips for Optimal Performance with Custom Alloy 455® Stainless Steel

When it comes to achieving optimal performance with Custom Alloy 455® Stainless Steel, there are a few key tips that can make all the difference. First and foremost, it’s essential to optimize your heat treatment process. This can help to ensure that your steel is as strong and durable as possible, while also maximizing its corrosion resistance. Additionally, it’s important to pay close attention to the composition of the steel itself, as well as its processing and finishing techniques. By selecting the right combination of factors, you can help to ensure that your Custom Alloy 455® Stainless Steel performs flawlessly, no matter what the application might be. Whether you’re working in automotive, aerospace, or any other industry that demands high-performance materials, it’s important to take the time to understand how to get the most from your Custom Alloy 455® Stainless Steel.

In conclusion, excellent performance can be achieved with CCustom Alloy 455® Stainless Steel when used in the right environment and conditions. The combination of stainless steel and Martensitic properties makes Custom Alloy 455® Stainless Steell a viable option for many applications that require superior corrosion, abrasion, and wear resistance. Moreover, it provides improved dimensional stability when heat treated and offers high strength, hardness, fatigue strength and fracture toughness in extreme loads and temperatures. With Precision Alloy Services Inc., you can rely on quality products that meet rigorous standards which will provide optimal performance to your projects. That being said, be sure to do your research before selecting the best alloy for your project so that you not only maximize its potential but also ensure its safety as well.

Precision Alloy Services is a specialty metals distributor and processor located in Bowling Green, Ohio. Precision Alloy Services’ quality management system is certified to ISO 9001:2015 and AS9100 Rev D, and we carry a large inventory of materials including nickel, cobalt, aluminum, and titanium alloys, stainless steels, and specialty alloy steels in a variety of sizes of sheet, plate, bar, and wire. Processing includes bar sawing, water-jet cutting, chamfering, and other services. Contact Us for more information. Custom 455 Stainless Alloy | Custom 465 Stainless Alloy