Alloy Blog

420 MOD (X15TN), ASTM F899: A Comprehensive Guide

420 MOD (X15TN) is a material that has been gaining in popularity in recent years. It is often used in the construction of products such as medical devices and equipment. In order to make sure that you are using 420 MOD (X15TN) correctly, it is important to be...

420 Stainless Steel Alloy: Properties and Applications

420 Stainless, 420(B), AMS 5621, ASTM F899 420 Stainless Steel alloy is a martensitic stainless steel that contains chromium and molybdenum as its main alloying elements. 420 stainless steel is known for its good corrosion resistance and high-strength properties. It...

Nitronic® 60® Austenitic Stainless Steel

Nitronic 60 is an anti-galling and wear resistant austenitic stainless steel. It provides a significantly lower cost alternative to combat wear and galling when compared with cobalt-bearing and high nickel alloys. The uniform corrosion resistance of Nitronic 60 is...

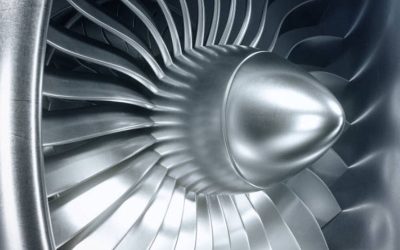

The Use Of Stainless Alloys in Aerospace

The Use Of Stainless Alloys in Aerospace One of the primary concerns in the aerospace industry is safety. When traveling at high speeds, whether on Earth or through space, there must be a complete assurance that everything about your vehicle will withstand the extreme...

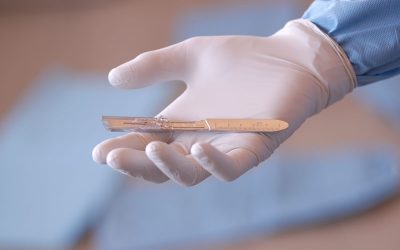

How Are Stainless Alloys Used in Medical Applications?

How Are Stainless Alloys Used in Medical Applications? Stainless alloys are popular in medical applications because of their inherent values. For instance, the material is durable and has natural corrosion resistance. However, many stainless alloys will do the job,...

What you Need To Know regarding Stainless Alloys

Need To Know regarding Stainless Alloys So, you're interested in learning more about the stainless alloy. Great! You're in the right place. Precision Alloys and Metals Ltd. is happy to provide you with the basic information about stainless steel alloys you need to...

Global High Performance Alloys Market to Reach $9.8 Billion by 2026

The global market for High Performance Alloys estimated at US$7.4 Billion in the year 2020, is projected to reach a revised size of US$9.8 Billion by 2026, growing at a CAGR of 4.9% over the analysis period. Non-Ferrous Metal, one of the segments analyzed in the...

Custom 465 Stainless Alloy end uses

Custom 465 Stainless Alloy end uses Custom 465® stainless is a premium, double vacuum-melted, martensitic age-hardenable alloy that offers an excellent combination of strength, toughness and corrosion resistance. The typical strength of this alloy can be as high as...

Custom 465 Stainless Alloy – General Description

Carpenter Technology’s Custom 465® stainless steel (UNS S46500) is a premium double vacuum-melted, martensitic, age-hardenable alloy that offers a unique combination of high strength, toughness, and corrosion resistance. When the alloy was first introduced to the...

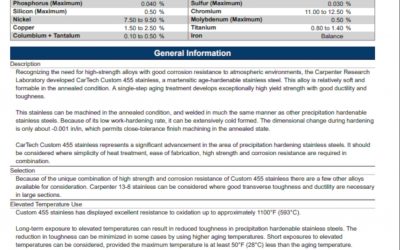

Custom 455 Stainless Alloy – General Description

Custom 455 Stainless Alloy - General Description Description Ultimately, with the need for high-strength alloys with good corrosion resistance to atmospheric environments, Carpenter Research Laboratory developed Custom 455® stainless. Correspondingly, a martensitic...

Understanding Custom Alloy 465 Stainless Alloy AMS 5936: Properties and Applications

In the ever-evolving world of materials engineering, the choice of alloy can significantly impact the performance, durability, and efficiency of components. Among the various specialized alloys available, Custom Alloy 465 stainless alloy, compliant with AMS 5936 standards, stands out for its unique properties and applications, particularly in the aerospace and medical sectors.

What is Custom Alloy 465?

Custom Alloy 465 is a martensitic stainless steel known for its high strength and excellent corrosion resistance. This alloy composition typically includes iron, chromium, nickel, and molybdenum, which together enhance its mechanical properties while maintaining a lightweight profile. The “AMS 5936” designation indicates that this alloy meets specific aerospace material standards, ensuring its reliability and performance in critical applications.

Key Properties of Custom Alloy 465

1. High Strength

One of the standout features of Custom Alloy 465 is its high tensile strength. This characteristic makes it suitable for applications that demand durability under extreme conditions. The alloy can withstand significant stress, making it ideal for structural components in aircraft and other high-performance machinery.

2. Corrosion Resistance

Corrosion resistance is another critical property of Custom Alloy 465. The alloy’s composition allows it to resist oxidation and other forms of corrosion, which is crucial in environments exposed to moisture and chemicals. This property extends the lifespan of components and reduces maintenance costs in the long run.

3. Heat Resistance

Custom Alloy 465 maintains its mechanical properties even at elevated temperatures. This quality is particularly important in aerospace applications, where components can experience significant thermal stress. The alloy’s ability to withstand high temperatures without losing strength makes it a reliable choice for engine parts and other heat-exposed applications.

4. Machinability

Despite its high strength, Custom Alloy 465 offers good machinability. This feature facilitates the manufacturing process, allowing for precise fabrication of complex components. Engineers appreciate the ease of machining, which ultimately contributes to faster production times and lower costs.

Applications of Custom Alloy 465

1. Aerospace Engineering

In the aerospace industry, where performance and safety are paramount, Custom Alloy 465 is frequently used in various applications, including:

- Aircraft Components: The alloy’s high strength and corrosion resistance make it suitable for manufacturing critical aircraft components such as landing gear and structural frames.

- Engine Parts: Custom Alloy 465 is ideal for components that operate under extreme temperatures and pressures, ensuring reliability and performance in flight.

2. Medical Devices

The medical field also benefits from the unique properties of Custom Alloy 465. Its corrosion resistance and biocompatibility make it suitable for:

- Surgical Instruments: The alloy’s durability ensures that surgical instruments can withstand repeated sterilization processes without degradation.

- Implants: In applications where physical integrity and biocompatibility are vital, Custom Alloy 465 is used in various implantable devices.

3. Industrial Applications

Beyond aerospace and medical, Custom Alloy 465 is used in various industrial applications where strength and resistance to harsh environments are required. This includes:

- Pumps and Valves: The alloy’s properties make it suitable for components in chemical processing where exposure to corrosive substances is common.

- Oil and Gas Industry: Custom Alloy 465 can be utilized in downhole components due to its ability to withstand harsh conditions encountered in drilling and extraction processes.

Why Choose Precision Alloy Services?

At Precision Alloy Services, we specialize in providing high-quality specialty metals, including Custom Alloy 465. Our commitment to excellence ensures that our clients receive materials that meet stringent industry standards. With a focus on customer satisfaction, we offer:

- Expertise: Our team is knowledgeable in metallurgy and can guide you in selecting the right alloy for your specific needs.

- Quality Assurance: We adhere to rigorous quality control processes to ensure that our alloys meet or exceed your expectations.

- Customization: We understand that every project is unique. We offer custom solutions tailored to your requirements, ensuring optimal performance for your applications.

Conclusion

Custom Alloy 465 stainless alloy AMS 5936 is a remarkable material that combines high strength, corrosion resistance, and heat resistance, making it ideal for demanding applications in aerospace, medical, and industrial sectors. By choosing Precision Alloy Services, you gain access to a wealth of expertise and high-quality materials designed to meet the challenges of modern engineering. Whether you’re developing advanced aerospace components or durable medical devices, Custom Alloy 465 is a versatile solution that can enhance performance and reliability.

For more information about our products and services, or to discuss your specific alloy needs, contact us today at (419) 725-6642 or [email protected].

This comprehensive overview of Custom Alloy 465 aims to inform readers about its properties, applications, and the advantages of utilizing Precision Alloy Services for their alloy needs.

Physical Address

726 Innovation Drive

Bowling Green, Ohio 43402